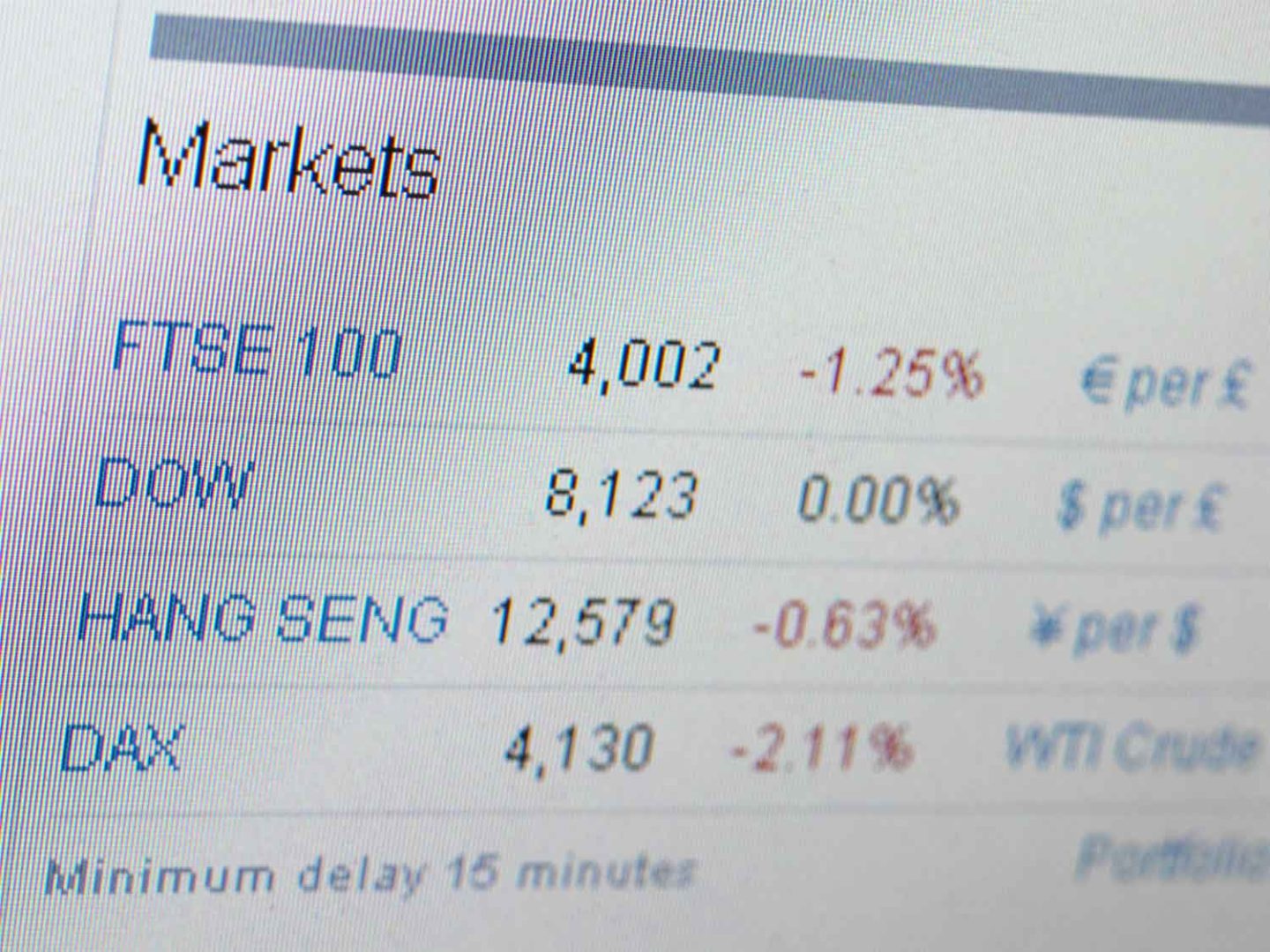

A recent study by the Boston Consulting Group, reveals that 72% of FTSE 100 companies now identify supply chain threats as a principal risk to their operations.

This heightened concern follows significant disruptions such as the Suez Canal blockage, the COVID-19 pandemic, and the Red Sea shipping crisis, which have exposed vulnerabilities in global supply chains.

Despite widespread acknowledgment of these risks, only 54 of the FTSE 100 companies have provided shareholders with detailed information on their mitigation strategies. This lack of transparency underscores the need for more robust communication regarding risk management practices.

To address these challenges, companies are implementing various strategies:

- Supplier engagement: Regular meetings with suppliers to monitor and share potential risks.

- Risk documentation: Compiling and updating ‘risk registers’ to document supplier-specific risks.

- Inventory management: Maintaining higher levels of ‘buffer’ stock to mitigate short-term crises.

- Diversification: Expanding supply chain streams to prevent business interruptions.

Technological solutions are also being leveraged to enhance resilience. Companies are implementing robust cybersecurity measures, utilising artificial intelligence for supply chain design and monitoring, deploying algorithms to identify high-risk raw materials, and conducting comprehensive assessments of suppliers’ financial resilience and infrastructure.

Supply chain risks have now reached the boardroom, with discussions taking place within executive and audit committees. This elevation in priority reflects the critical importance of supply chain stability to overall business operations.

The findings emphasise the necessity for businesses to prioritise transparency, technological innovation, and strategic planning in their supply chain management. As risks continue to evolve, proactive risk management has become a vital component of corporate governance.

Metro’s advanced supply chain technology

Metro’s proprietary cutting-edge supply chain technology has been conceived and designed to enhance visibility, control, and efficiency. The AI-driven solutions provide real-time insights into supply chain operations, enabling companies to anticipate disruptions and respond swiftly. Features include comprehensive purchase order management, multi-modal track and trace capabilities, and consignment management tools. Additionally, the MVT ECO platform allows shippers to forecast, measure, and offset global supply chain emissions, supporting sustainability goals. By integrating these technologies, businesses can strengthen their supply chain resilience and maintain operational continuity in an increasingly complex global environment.

Metro is leading the industry in developing the technologies and platforms that simplify and support the development of resilient, agile and adaptable supply chains.

Visibility, control, environmental, and customs modules, blend together with integrations of critical digital trade documents, to provide an unparalleled supply chain platform.

EMAIL Ian Powell for further Information on our digital capabilities and how we can protect and enhance your global trade and business growth ambitions.